|

||||||||||

| This is an excerpt taken from April,1948, Rayon Yarns and was written by "Barney" Barnette who reprints a large portion of J.P. Hannum's notes in this article. J.P. Hannum was the chief engineer who directed the construction of the original units of the Rayon Plant and the rehabilitation of the village. | ||||||||||

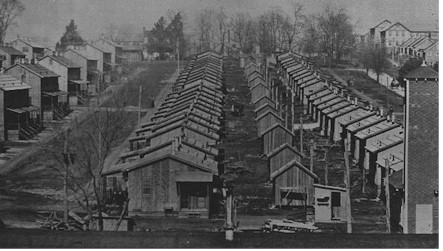

The one optimistic note was the enthusiasm of the people. The local populace received the arriving Du Ponters with open arms and they were treated like visiting royalty. A newspaper reporter was assigned to cover developments as they progressed and virtually became Mr. Hannum's shadow for the next several weeks. It seemed evident that the people were expecting a repetition of the wartime episode - a boom town again. But this time the pace was not destined to be so rapid, yet, as the years have proved, the ultimate results are much more permanent. But as to the appearance of Old Hickory in the autumn of 1923, here's the way it looked to Mr. Hannum: Most of the area in the vicinity of the present plant was covered with ruins and foundations of war-time buildings. The streets, with the exception of the concrete road running through the village, were full of ruts and ditches, making many of them almost impassable. The old network of wooden sidewalks which had kept thousands of powder plant workers from miring ino the mud were rotting away and the remaining sections were harbors for rats and snakes. The houses themselves were pathetic monuments to the folly of neglect. Only about fifteen per cent of them were occupied and most of these were in a terrible condition and barely livable. Porches were falling in and roofs sagging, making it even hazardous to enter many of them. The Nashville Industrial Corporation had sold many of the houses and these were in various stages of being dismantled. And then there were the two-story apartment buildings, more commonly known as "tarbabies," which had been built when expediency and not beauty was the primary objective. These alone were enough to give the village a grisly appearance.

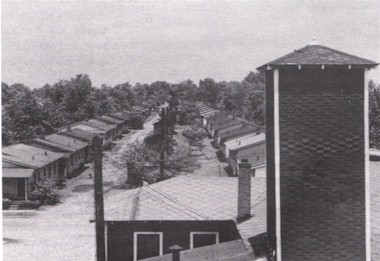

Madison was still a rural community - general store, bank, blacksmith shop and a few houses. Rayon City was open fields and the area now covered by Dupontonia (now Lakewood) was covered with partially completed houses left just as they stood when wartime activities ceased. The original purchase by Du Pont extended only as far as 15th Street and did not include the area which at that time was called the "St. Louis" area (because of its purchase from N.I.C. by a St. Louis company) and later known as "New Town." This trail-blazing force of engineers set up their headquarters in an old wartime building which stood in the area where Plant 2B now stands. With temporary shops established in another "powder plant" building, they set about hiring carpenters, painters and plumbers to initiate a face-lifting for the village and make the houses livable for future Du Ponters. Much of the plumbing had been removed from the houses and had to be replaced. The old wallboard was removed and replaced with new and all other necessary repairs made, climaxed by a paint job.

Soon after the construction of the plant was started, paving of the streets and laying of concrete sidewalks began. In the spring of 1924, plans for actual construction of the plant units were reaching completion. However, one important job had to be completed before the actual building could commence. Within the area selected for the plant site, there were three graveyards. Tennessee law required the moving of all marked graves if the burial grounds were be be used for other purposes. One of these graveyards, which was adjacent to the old "brick church," or just about where the settling basins of the present-day filter plant are now located, was the burial grounds of a group of people about which there is little factual information available. This group, which has been called "the Free Nation," was a dark-skinned race who had moved into Hadley's Bend sometime prior to the Civil War and had worked as tenant farmers. The origin of this group of people is not known, nor is there any knowledge of their descendants. However, it seems they had received permission from the Hadleys to bury thei r dead in this particular plot. There was another group of unmarked graves located southeast of this graveyard, and a slave burial plot located where No. 2 Power House now stands. So the skeletons from these graves had to be removed and properly reburied before the beginning of the first construction work. On April 30, 1924, almost in the shadows of "Vaucluse," the anti-bellum manor house of the historic Hadley plantation, ground was broken for the first units of a manufacturing installation destined to have a decided effect on the economy of the community in the years to come.

When work really got under way, approximately 400 workers were engaged in the simultaneous construction of the various necessary buildings. However, Plant 1 Chemical Building was actually the first unit started, since these plans were the first received by local engineers from the Wilmington Engineering office. The original plans called for the construction of a 22-spinning-machine unit of the "bobbin process"" type. However, before complete plans were received for this type installation, the "bucket process" of rayon manufacture was developed in France and all plans were scrapped until an investigation of this process could be made. This change of plans caused a brief halt in construction in the early winter of 1924 and this of course had a decided effect on the local community. To quote Mr. Hannum: The enthusiasm and local morale dropped like during the depression of 1929." The rumor-mongers and gloom-casters could find no answer to this temporary cessation, other than Du Pont had abandoned their plans for a rayon plant in this locality. This work stoppage, however, was short-lived, and activity soon resumed, until January 15, 1925, the first spinning machine started humming.

|