|

|||||||||||

| Re-Inventing Inventions

Rayon Record, March 27, 1959 A young sprout we know, not ordinarily much interested in water except for drinking purposes, looked up from his history book and whooped. "These people are cuckoo. One place here they say that Romans at the time of Christ had bathrooms with hot and cold running water, central heating, and other stuff like that. Then later," he said, "they talk about the famous Palace of Versailles built by Louis XIV in France only a couple of hundred years ago, and they say it had no conveniences. That's impossible." But it's not impossible. What happened was that the technology responsible for the Roman conveniences was destroyed - lost to mankind. Their inventions, like many that came after, had to be re-invented before they found their way into modern life. We think this is noteworthy. We, like all Americans have seen industry perform so many feats which improved human welfare that we come to think progress is automatic and inevitable. It isn't. Industry was built by men and it can be destroyed by men. If the U.S. continues to move forward, it will because it preserves the conditions which promote progress. Industry must be encouraged to grow, to vary its efforts, to promote research, and to profit by its ventures. By the same token, any measures which tend to penalize success or prevent the growth of an industry that has proved so fruitful will retard progress. |

|||||||||||

| BUBBLFIL

I do not know what happened with "bubblfil" and could not find any reference to it. Don't be deceived this not the bubblefill we know of as packing material today. Is this a possible reinvention for someone someday? |

|||||||||||

Some people call "bubblefil"

cellophane bubbles. Others refer to it as rayon beads.

Actually, it is neither, and yet, chemically, it has qualities similar

to both.

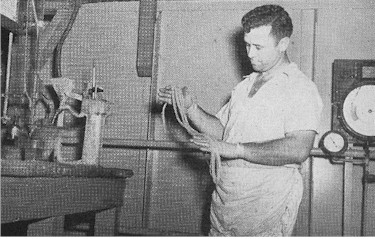

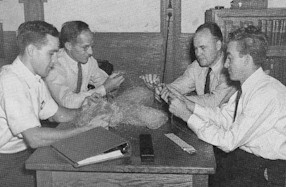

We all know that rayon and cellophane, made by the viscose process, are pretty much the same material, namely, regenerated cellulose. In one instance the syrupy viscose material is forced through the holes a spinneret to make a fibrous thread and in the other it is rolled out into a solid sheet of film. "Bubblfil" comes from the same viscose. Like rayon it is extruded from a spinneret, but in addition, a small amount of air is injected into the relatively large thread at regular intervals, causing the transparent bubble-like appearance which might lead some to think of the product as a continuous stream of tiny cellophane packages of air. At any rate, the resulting material opens up a large field of interesting possibilities for its application. Its toughness, buoyancy and resiliency are properties which mark it particularly for important roles in this war of materials. The Company has developed it as a substitute for imported kapok in life jackets and life rafts, or as a shock-absorbing material to do the work of scarce sponge rubber in airplanes, tanks and other military vehicles.

Tests already made show that the cellulose bubbles are fully as buoyant as the imported kapok, which comes from the seed pod of Javanese tree. The new product has been considered for life jackets of the type worn by U.S. Navy personnel, for which kapok heretofore has been used. "Bubblfil" has also been tried in the air compartments of life boats and life rafts where kapok is no longer being used because of the limited supply. It is also proposed for bridge pontoons, formerly filled with sponge rubber. If these air compartments are punctured by bullets or falling debris the "Bubblfil" will keep the craft afloat. It has proved entirely satisfactory as a replacement for kapok in aviation tow targets, where buoyant material is used to keep the targets afloat when they are shot down. Neither kapok nor cellulose bubbles can be classed as non-flammable but the bubbles will not ignite when struck by tracer bullets. This gives "Bubblfil" a distinct advantage in military applications of many kinds. It is even possible to render "Bubblfil" flame-resistant by chemical treatment. In life jackets or life rafts "Bubblfil" has another advantage, for it loses buoyancy less rapidly than kapok upon prolonged immersion in water. Tightly packed "Bubblefil" weighs about 1.5 pounds per cubic foot and will support 20 to 30 times its weight of lead. Less than three pounds of the material will keep a heavy man's shoulders out of water.

The bubbles cannot be broken by squeezing, nor will they rupture at extremely low pressures of high altitudes. The bubbles remained intact in laboratory tests equivalent to an altitude of over 50,000 feet. The material also is quite stable to extremes in temperature. Heating for three days in air at temperatures above 200° F and chilling to 28° F degrees below 0° F did not break the bubbles. The material is so tough that its buoyancy was not affected when cheesecloth bags filled with it were subjected to an impact of 79 foot pounds per square inch, equivalent to the impact sustained by a lifejacket worn by a 200 pound man upon striking the water after jumping from a height of 55 feet. The resiliency of the cellulose bubbles, a property derived from the "springiness" of the entrapped air, has encouraged the Company to study their suitability as a shock-absorbing material. Here "Bubblfil" might replace sponge rubber or so called "cellular rubber," so very scarce today. The "Bubblfil" has been formed, by means of an adhesive material, into mats and cushions. These might be used for padding in airplanes or tanks. Bullets will not shatter them, leaving only small holes. A third important characteristic of "Bubbfil" is its low thermal conductivity, that is, its insulating property. Air is a good insulator. "Bubblfil" is a mass of air cells and can be used as a stuffing and as an insulating layer. Experimental fabrics have been woven, with cotton thread running in one direction and strands of "Bubblfil" in the other. This extremely lightweight material could be used as an interlining for cold weather jackets or flying suits, or several layers could be used as the filler for sleeping bags. The size and spacing of the bubbles, which are streamlined in shape, may be arranged according to choice. Much of the bubble-strand now being made has bubble a little more than a quarter of an inch, running three to the inch. A smaller size is also made. As has been indicated, "Bubblefil" is exclusively a Rayon development, and aside from the original research, men at Old Hickory have been largely responsible for the results. If "Bubblfil" becomes important commercially or in the war effort, tanks must go to our technical staff and men in Mechanical and Chemical Assistance and to those constant guardians of its production - the operators who tend it day and night. |

|||||||||||