|

|||||||

| From telegraphs to bike messengers, our site has seen a variety of methods to communicate with our peers. It is difficult to believe in this day of instant messaging that it was not long ago that we had to rely on what is considered today to be crude forms of communication. Somehow, the site flourished without email in the earlier years. :-) | |||||||

|

Telegraphs Old Hickory News - August 1939

"Lots of jobs as telegraph operators have been inherited. You know, a son will learn from his father how to tap out and receive messages, and eventually take over when the father dies. But I just sort of happened into mine." The speaker was Billie Miller, who has operated the telegraph keys for Old Hickory for fourteen years. Billie says she just hung around the telegraph office in Paris, Tennessee, her home, and picked up enough to start her in the profession. Her choice for work wasn't exactly an ordinary one for girls, but today the number of women operators is increasing. "There wasn't anything particularly significant about the date I began work in Old Hickory, either," Billie adds. That was April 1, 1925. The telegraph office was first located in the Tennessee Central Depot, where she started here. Then it was moved across the road and to its present spot inside the plant building. Undoubtedly, Billie has had much of the story of Hickory pass under her finger tips since that day in 1925. "This village isn't the only thing that has changed around here," stated Billie with her familiar grin. She was talking about the telegraph system itself. For a long time, machines were used which required the operator's mastery of the Morse code, the dot-and-dash system. Like many another "pounder of the key" Billie watched her finger become flattened at the tip from constant tapping. Then came the Simplex automatic which operates on electric impulses and prints the message on tape. The words are typed on a machine very similar to a typewriter, and without any dot-and-dash business goes out over the wires. Billie had to go away and take special training for this, but today she can call on either method. Incidentally, she describes the newer system as very completely even without having to know the Morse code. "I'd say an improvement in living conditions and the physical appearance of the town," Billie offered when questioned as to the biggest change she has noticed in the community of 1939 as compared to that of 1925. |

|||||||

Number

Please? .....Telephones

Rayon Yarns - April 1940 |

|||||||

|

How many of us have ever

stopped to think who answers "Number please" when we take down

the telephone receiver in the plant to make a call?

The telephone system links all parts of the Rayon and "Cellophane" plants. The operator asking "Number, please" can place us in communication with any area of the plant within a few seconds. The plant telephone operators who render such fine service merit the praise and appreciation of plant telephone users. In the accompanying picture are shown the four telephone operators who serve the Rayon and "Cellophane" employees. Mrs. Nelle J. Stier was the first telephone operator of the Old Hickory plant. Her service dates from April 19, 1926. The telephone room was located in Plant No. 1 Shipping and Mrs. Stier was the only operator at that time. In the spring of 1927, the location of the switchboard was changed from Plant No. 1 Shipping to its present location, which is on the floor where First Aid is located, and next to the Plant Manager's office. Mrs. Fannie H. Gamble was employed in June of 1933. The efficient and courteous service rendered by Mrs. Gamble and Mrs. Stier are appreciated by the entire plant personnel. Assisting Mrs. Stier and Mrs. Gamble are two relief operators. |

|||||||

|

|||||||

|

The

Teletype Machine |

|||||||

|

|

|||||||

|

DuPont's new Teletype Network went into operation last month connecting approximately 110 DuPont plants, sales offices and main offices with one another by means of ultramodern automatic teletypewriter hook-up. The network, which is leased from American Telephone and Telegraph Companies and associated Bell Companies, consists of an automatic switching center located in Wilmington and thirteen two-way high speed lines that interconnect outlying locations. Integrated with this are six teletype distributing systems that provide service for the DuPont offices located in certain metropolitan areas. Messages are directed through the system by short directing codes inserted on perforated tapes in front of the message text. The transmission of messages is entirely automatic from the time the tape is placed in a transmitter until the printed message is removed at its destination. The network has been engineered to provide a maximum average delay of 15 minutes during the busy hours. Faster service will be obtained at other times. The network was installed in order to handle company written wire requirements at a lower cost than the commercial wire companies and also provide faster service. It will also guarantee continuity of service between Company locations during emergencies. |

|||||||

|

|

|||||||

|

|

|||||||

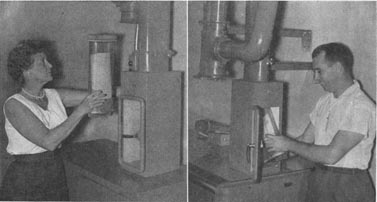

| The

Pneumatic Method

Audrey Smith, Planning, and Buddy Beaty, Tabulating, are pictured here in the process of sending and receiving messages between the two sections through recently installed pneumatic tubes. The installation of the pneumatic tube system between Tabulating and Planning has greatly speeded up communication between these sections. Prior to this installation, all papers pertaining to customers' orders and invoices were delivered by messenger service. Since good customer service assures a greater measure of job security to all of us, it is important that customers' received on the plant (in Tabulating) be transmitted to Planning as soon as possible so that they may be entered into the plant production schedule. Once the order has been produced and shipment made, the customer is billed promptly so that all accounting procedures can be completed as rapidly as possible. |

|||||||

|

|

|||||||

| Computer Evolution |  |

||||||

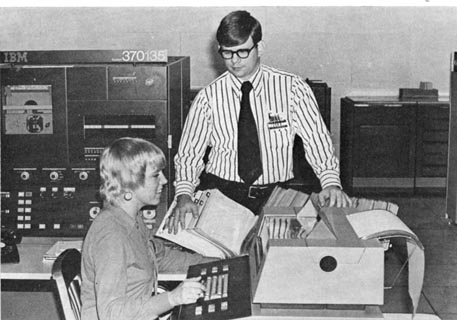

| Computer

Streamlines Credit Union Services February 4, 1972 - Old Hickory Record This is Old Hickory's IBM System/3 computer equipment. Computer Operator Vivian E. Fudge is using a data recorder, and other components, from the left, are a line printer, a processing unit and a multi-function card/disc storage unit. A powerful, compact computer system tucked into a nearby office is given chief credit for improved service offered by the Old Hickory Employees' Credit Union office these days. Waiting lines are shorter, more information is available to members and credit union employees are left with more time to efficiently run the members' business. Installed early last year and operational in August, the computer is an IBM System/3, relatively new equipment that permits fast and accurate posting of accounts and performs any number of functions that add to credit union efficiency. |

|||||||

| Computers:

Where Change is the Only Certainty January 4, 1974 - Old Hickory Record For the fourth time since computers were introduced here just 15 years ago, a new generation machine, the IBM System/370, has been brought into operation. The new central computer is only one of numerous computer systems either installed or planned for this site in upcoming years. Several of the changes involve computer use in manufacturing areas.

Computer Clerk Bette Ellis, Systems Analyst Tom Patton with the IBM System/370 Four Generations in 15 years. |

|||||||

|

Computers in the Plant

|

|||||||

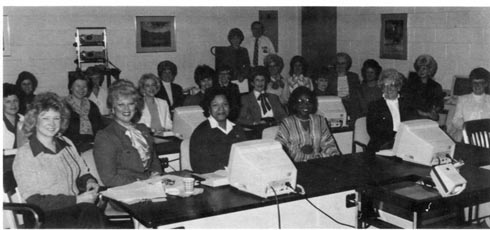

| Computer Revolution

is Here - Many Paper Record on Way Out Old Hickory Record March - April 1985 Fed up with paperwork? Constantly behind in your mail? Such problems may soon be in your past. The computer revolution is here and promises to cause more than a blip in the way many will be performing their jobs. Seven new computer systems are scheduled for installation at Old Hickory in the near future - all designed to improve the site's effectiveness in better managing its tremendous volume of information. These systems will "put us well on our way to a 'paperless' environment," said Richard Grand, systems project coordinator. "Time cards ... employee job histories ... you name the record, and chances are, it will be converted to a computer form - and be eliminated as a paper record. " Richard described several developments on the horizon: Supervisors will use computer screens to record pay information and electronically send it to the payroll office. This will eliminate the need for time cards. Employee records, from the date of being hired until after death, will be kept on a computer. Whenever an employee changes jobs, notations will be made electronically. Among other records to be kept in a computer are employees' days of rest and vacation schedules. A large volume of mail will be transmitted electronically. Information will be communicated almost instantaneously, reducing the volume of "paper mail" which can take days to receive. Results of the changes are predictable enough. Richard noted that future plant offices "will use fewer typewriters, file drawers, copy machines and calculators - their places taken by a computer terminal. I've reduced my own file drawers from eight to just one, plus what I have in my desk," said Richard who has used electronic mailing and filing for three years. "To say that this will be an exciting time for many employees -- especially those in offices - may be understating the case," he said. "I think everyone will find that as we change from the 'old' way to the 'new' computerized way, that these systems are tools that will help us do our jobs more efficiently." He listed the following systems to be installed: APR - Administrative Personnel Records CFAS - Cost and Financial Analysis System EIS - Engineering Information System MMS - Material Management System CFPM - Centralized Finished Product Management System PQM-EF-Product Quality Management In order for these systems to be accessed from a single terminal, a "broadband" system is being installed. This consists of a cable (like cable TV) which connects the terminals to many site computers. To help Old Hickory prepare for the "computer revolution", a general computer training course called COMTRED is being offered to an estimated 500 employees as a first training step. A new computer training center in Data Systems has been established for this. A "learning center" has also been established. |

|||||||

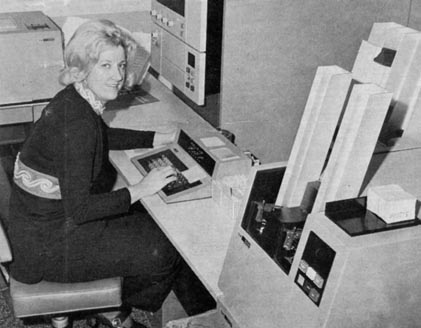

Sue

McCrary of the Order Section will operate the equipment located on our

plant. She, along with Mrs. B.L. Wooten and about 200 Du Pont employees

from other locations received special training in the intricacies of the

operation in Wilmington recently.

Sue

McCrary of the Order Section will operate the equipment located on our

plant. She, along with Mrs. B.L. Wooten and about 200 Du Pont employees

from other locations received special training in the intricacies of the

operation in Wilmington recently.