|

||||

|

The job list from the Rayon years

looks extremely different from the list of today. These were the

years where employees were paid on site and didn't have checks magically

appear in their checking accounts over night. These were the years

that DuPont was concerned about what was fed to employees in the

cafeterias. These were the years that called for a DuPont

employee to be sent to your house to change a light bulb. As

nostalgic as these jobs may sound, the job list of today would probably

cause just as much wonderment to our predecessors from the Rayon

era.

The following is a list of a few of these jobs that were a part of the Rayon plant that are fairly extinct today due to the changes in how we live our lives. |

||||

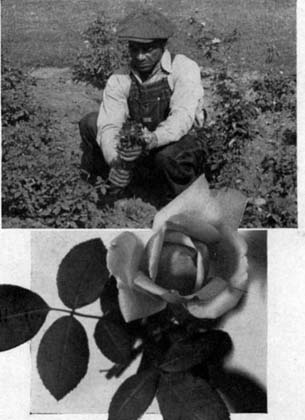

A

familiar scene is Harry Branum, Jr., working with his flowers. Also a

familiar scene is Harry's daily presentation of bouquets to the lucky

people who work closest to the plant lawn. No small morale builder are

these bouquets of brilliantly hued roses, or the showy many-colored

Zinnia, or a mixture of Marigold and Blue Ageratum. Harry Branum, Jr.,

full-time gardener, is supervised by F.E. Smith, Jr. Harry's service

dates back to 1932, and he makes his home in Edenwald, Tennessee. -

Rayon 1946 A

familiar scene is Harry Branum, Jr., working with his flowers. Also a

familiar scene is Harry's daily presentation of bouquets to the lucky

people who work closest to the plant lawn. No small morale builder are

these bouquets of brilliantly hued roses, or the showy many-colored

Zinnia, or a mixture of Marigold and Blue Ageratum. Harry Branum, Jr.,

full-time gardener, is supervised by F.E. Smith, Jr. Harry's service

dates back to 1932, and he makes his home in Edenwald, Tennessee. -

Rayon 1946

|

||||

|

Although you cannot tell much about this photo since it is in black and white, this is a massive and probably very colorful display of Red Salvia and Periwinkle flowers that use to grace the front of Rayon. If you can imagine, this particular flowerbed was somewhere in the vicinity of where the Medical/Reemay® entrance is today. This flowerbed was one of the few that Branum was responsible for in his duties as a plant gardener. |

||||

|

|

||||

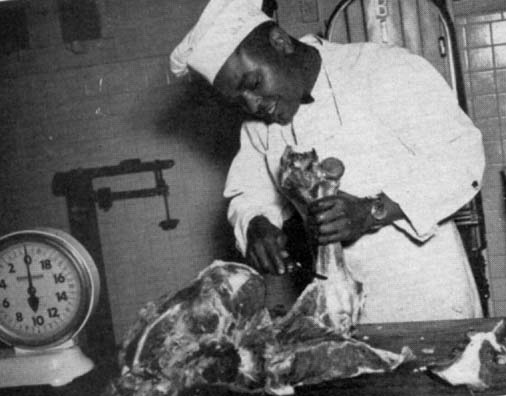

| You would not ordinarily connect the occupation of butcher with the manufacture of rayon, but this is one of the many and varied jobs that go to make up our organization. Hudson Cantrell is the plant butcher. He handles the handling and preparation of meat for the plant cafeterias. An average of about 400 pounds of meat a day, raw weight, is used on the plant. One of our returned veterans, Hudson served in the Army for nearly five years. He became a platoon sergeant with a truck outfit and was in the Philippines campaign and later in Japan. He has married since discharge, lives at Goodlettsville. Hudson learned to be a butcher since returning to work in February of last year. Cafeteria menus are carefully worked out to provide a balanced diet and meat is the main source of protein, the body-builder, besides furnishing vitamins, minerals and energy fuel. Doctors tell us the ideal diet for the average individual includes at least one serving of meat every day. - Rayon - 1948 | ||||

|

|

||||

|

The following jobs are

from the early 1950s. The Rayon Record ran a series of articles in

each edition called "This is My Job". Here are a few of

those articles. |

||||

|

“Robbie” was first employed on the plant in

1939 and entered the army in June, 1942.

Upon receiving a medical discharge in October, 1944, he returned

to his job in December of that year. “Robbie” was the first wounded veteran of World

War II to return to work on the plant and received the Purple Heart and

Oak Leaf Cluster because of these wounds. The Robertson family, consisting of “Robbie,” his wife and two small daughters, make their home in Mt. Juliet. |

||||

Comer has been in this department for the past 18 years, having worked in Shipping for 2 ½ years and in Spinning for 2 ½ years. His adjusted service date is November 17, 1928. |

||||

|

|

||||

|

Having an adjusted service date of August 7, 1933, “Bob” has been in Plant Service for the past eighteen years, fifteen of which have been spent as Garage Mechanic. Prior to his employment in Plant Services, “Bob” spent three years in Spinning Areas. Jean George and Wilma Blanton are shown checking

card records as part of their job as Employment Record clerks.

Their job consists of keeping employment information on all

hourly roll employees from the date of employment Records are kept on

changes of job status, rates of pay, payroll numbers, periods of

disability, vacations and information pertaining to employee insurance

beneficiaries, seniority, etc. Jean has been a Records Clerk for the past two

years, having previously worked as Employment Sign-Up Clerk for four

years. She also worked in

Production control Section for about nine months. Wilma has been in Employment for the past four years, having transferred from Time Office where she was a clerk for eight years. Prior to that time, she was in the Inspection Area for five years. |

||||

|

When a padlock key is needed, Perry makes a new one

from either a sample or from the knowledge of working tumblers of the

lock. He is also required

to repair and rebuild locks of all kinds and keep them in working

condition. Perry has been on the job for the past five years, having been with the Millwright Group since 1925. |

||||

|

Tom has been with the Village Maintenance Group since December, 1948, having been employed at the time as an outside Carpenter. He was transferred to his present job 2 ½ years ago. |

||||

|

Having been employed as a cake wrapper in 1929, “Jack” worked in the Spinning areas until October, 1936, when he was transferred to Maintenance as a Painter. He was assigned to his present Sign Painting job in August, 1946. His adjusted service date is June 29, 1921. |

||||

|

Clifford has been on his present job for 14 years. He had previous service in 2-A Wash and Bleach Laboratory, where he helped mix F Finish solution. He also worked for a while in the Spinning area and in the Wash Court as a wringer operator. He came to work for the company in January of 1927. |

||||

|

Eva was first employed in Plant 2A Reeling Room as an operator in 1933, and transferred to the Medical Department 11 years ago. She has been on her present job for the past five years.

|

||||

|

|

||||

|

Omel has been operating this and the

electrically-operated type lifts for the past eight years and in

addition to material mentioned above, he unloads wood pulp, using the

electric lift for this purpose. |

||||

|

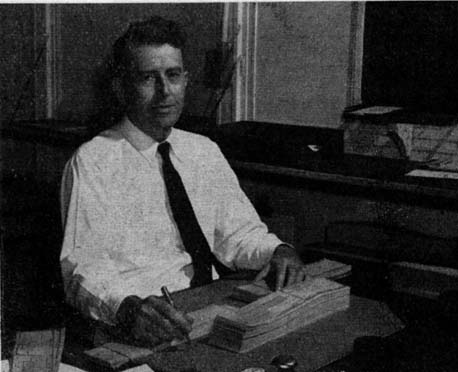

All employees’ checks are received in the

Cashier’s Office and dated, signed and distributed.

That office also has the responsibility of getting disability

checks to employees out

sick. All cash from

miscellaneous sales, etc., is also received there. Charlie has been a Du Ponter for 24 years. His first job was Plant 1 Spinning. He quit there to return to school and was later rehired in the Time Office. He has been on his present job since…….. with the exception of about two years during World War II, when he worked in the Maintenance Office doing machine and shop scheduling. |

||||

|

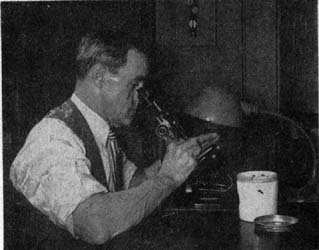

The job is done with a small reamer under a microscope. With the exception of a short time spent in the Wash and Bleach, John has been in his present job for the past 25 ½ years. His adjusted service date is April 19,1925. |

||||

|

Charlie

Watts has a job that is important to every employee.

Charlie

Watts has a job that is important to every employee. John

H. Emerson is a Spinnerette Repair Operator in Plant 1 Spinnerette Room.

John

H. Emerson is a Spinnerette Repair Operator in Plant 1 Spinnerette Room.