|

|||||

| Most of you know the story and image behind Rosie the Riveter. Thousands of women across the country went to work to fill jobs vacated by men leaving for war. Rayon, Old Hickory was no different than any other manufacturing facility in America in that there was a need for women to step into jobs traditionally held by men. The following is an article from the June, 1943, Rayon Yarns about a group of "Rosie the Riveters" in our history. Note: This article was slightly edited to remove an opinion of the author which could be construed as highly offensive today. The integrity of the article has not been affected by this edit. | |||||

|

|

|||||

|

Women lounge on the front lawn of Rayon in 1943. |

|||||

New Hands Keep Them

Turning

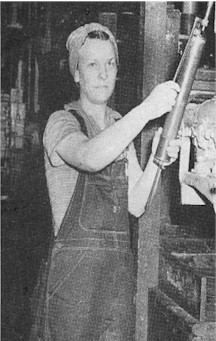

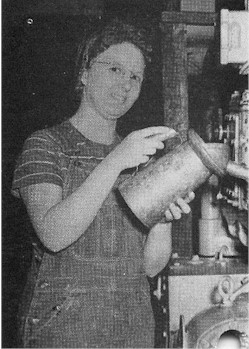

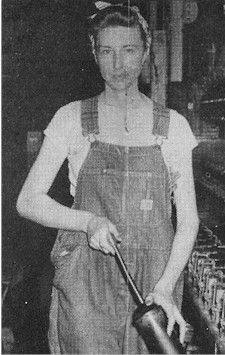

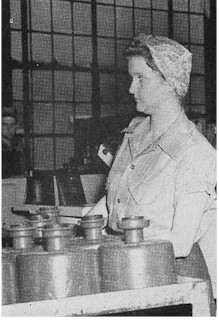

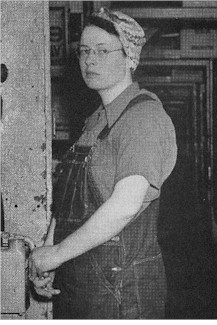

On March 4, 1943, a rather drastic change was made in the personnel of the Lubrication Department, for on this date the first of the girl oilers began work in Plant 1 Spinning. This change, made necessary by the shortage of manpower due to the war, has been very satisfactory. When we think of oiling spinning machines, three piston pumps, gears and compensators we usually think of it as a man's job, but it's all in the day's work to the girl oilers. In 2B Spinning Room Jessie B. Eaton and Frances Norton carry on just as efficiently as any man, while in Plant 1 Spinning Lillie M. Keith, Jessie M. Hunter, Tina M. Adams and Elizabeth Robertson are doing the same type work. Since the first girl started work on March 4, we have had a total of nine to come to the department. Just recently Ida C. Holloway, whose first job was oiling in Plant 1, has been transferred to the Electrical Department, while Nettie C. Butler from 1D Spinning was sent to the Bucket Shop. It was my privilege recently to watch the girls perform some of their tasks and, judging by the calm, efficient way in which they went about their work, it would seem that they had always worked in these unfamiliar surroundings with the constant hum of machinery in their ears. I learned by talking with them that their general schedule is carried out in this manner. First thing each morning, they get their flashlights and check the entire section of the room assigned to them. This is called "high-spotting" the section and enables them to tell if any machine is dangerously low on oil and should be oiled before the schedule time. On this "high spot" trip they also carry rags to wipe up any oil that may be on the floor. Housekeeping, which is checked daily, is an important item. The girls ride along on little buggies and, using clean rags, they mop up all grease on PIVs, compensators and motors as they roll along from one machine to the other. They also check the floor for oil and wipe the oil out of the drip pans under the end gear. The dirty rags are disposed of by putting them in a barrel especially designed for this purpose. Perhaps the most difficult of all the job is "shooting pump heads." This is done on Monday, Wednesday and Friday, and is considered the hardest trick in the bag to learn. The girls, however, after a little practice, handle it quite nicely. Other jobs are oiling pump gears, checking and oiling chain housing, checking and oiling PIV's and compensators, filling lubricator bottles, oiling lubricator ratchets and plungers, oiling drive motors and filling grease guns. The girls wear overalls while at work for theirs is a rather dirty job. At the end of the day, however, they have a chance to take a shower and change into something neat and clean, for modern, up-to-date showers have been installed for the girls to use. Seeing them pass out the gate at 4:30, all scrubbed and lipsticked, one would never know that they had just finished a man-sized day's work under the same working conditions that the men have and yet managed to emerge with that feminine charm intact. Our hats are off to these girls who fill men's jobs so efficiently and who don't hesitate at the sign of a little dirt and grease. This is the type of women who will set their shoulders to the wheel and keep things going for the duration. |

Ida C. Holloway working on extension cord, Electrical Department, Combined Shops

Tina N. Adams greasing end gear bearing on Type 5 spinning machine.

Lillie C. Keith adding A-18 oil to PIV, Type 5 spinning machine.

Jessie M. Hunter oiling three-piston pump heads, Type 10 spinning machine, Plant 1

Frances E. Norton filling 2-gallon can with A-18 oil, Plant 1.

Nettie T. Butler waxing spinning buckets.

Jessie B. Eaton pumping farval system which oils feed wheel shaft bearing, rocker arm shaft bearing and viscose pump shaft bearings. |

||||